Mercury 9.9 HP Runs Too Lean (1994-2001)

The title “Mercury 9.9hp Outboard Runs Too Lean” refers to a situation in which the fuel-to-air ratio within the combustion process of a boat motor, specifically the 1994-2001 year 2-stroke Mercury 9.9hp outboard engine, becomes imbalanced. In this scenario, the engine operates with a higher proportion of air in comparison to the amount of fuel being delivered for combustion. This disparity between fuel and air can result in a range of distinct symptoms. During idle, the boat motor may struggle to maintain a smooth and consistent speed, often leading to stalling or uneven operation. Notably, the exhaust emissions may appear lighter or more translucent than usual, indicating an incomplete fuel burn. Moreover, this condition can result in diminished power output, causing sluggish acceleration and reduced overall performance of the boat motor. Addressing this issue entails a thorough approach, which includes fine-tuning the fuel delivery system, potentially cleaning or replacing relevant components, and ensuring meticulous adjustments to achieve the appropriate fuel-to-air ratio. By rectifying this imbalance, the boat motor can regain its optimal functionality, running smoothly both at idle and across various operational conditions.

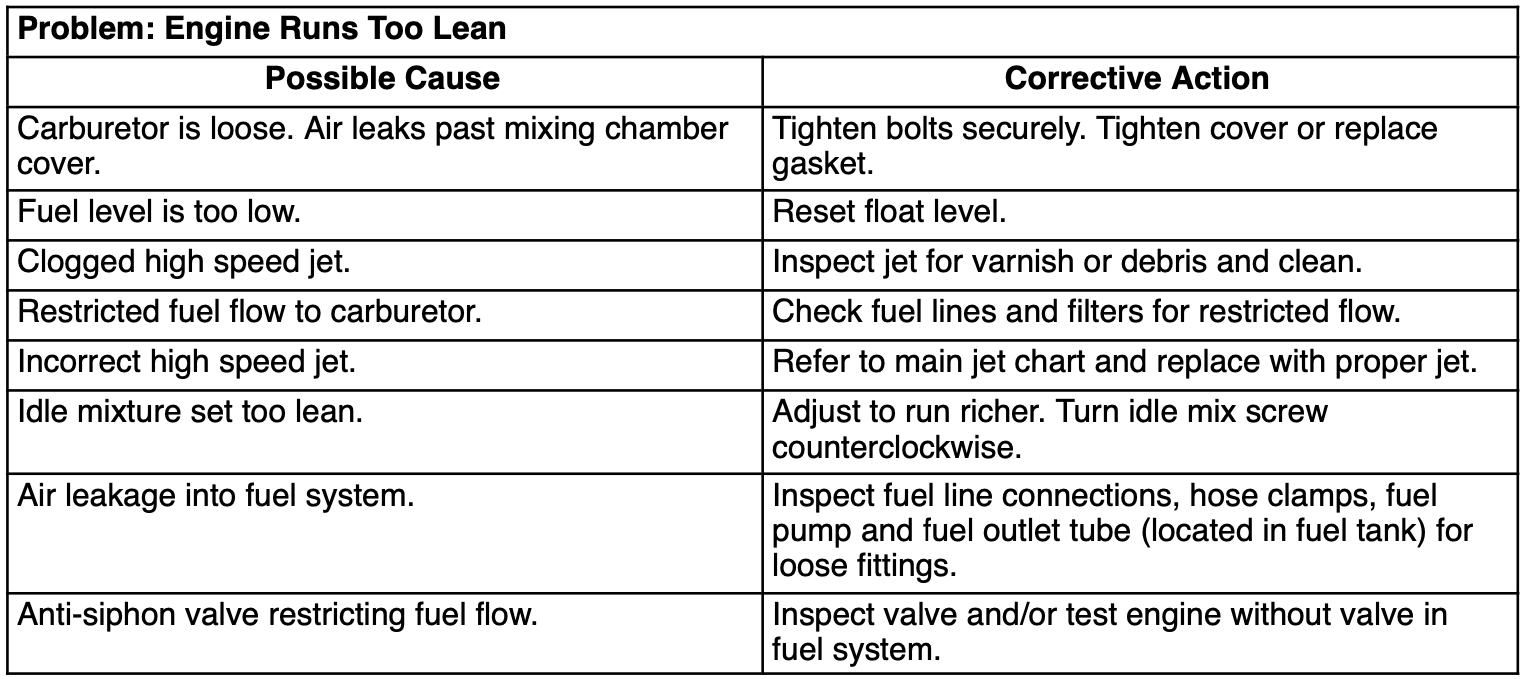

Mercury Engine Runs Too Lean

In this article, we’ll look at why a Mercury 9.9hp outboard engine might be running too lean and show you how to make it run better by fixing the issue.

Carburetor Loose and Air Leaks:

One potential culprit behind a lean-running engine is a loose carburetor, allowing excess air to enter the mixing chamber. This can disrupt the proper fuel-to-air ratio needed for efficient combustion. To address this, it’s crucial to secure the carburetor bolts tightly and inspect the mixing chamber cover. Tightening the cover or replacing a worn gasket can prevent air leaks and maintain the necessary balance of fuel and air.

Low Fuel Level and Clogged High-Speed Jet:

A low fuel level in the carburetor’s float chamber can lead to insufficient fuel supply, causing the engine to run lean. Adjusting the float level to the manufacturer’s specifications can ensure a consistent fuel supply. Additionally, a clogged high-speed jet can restrict fuel flow. Regularly inspecting and cleaning the jet, ensuring it’s free from varnish or debris, can help maintain optimal fuel delivery.

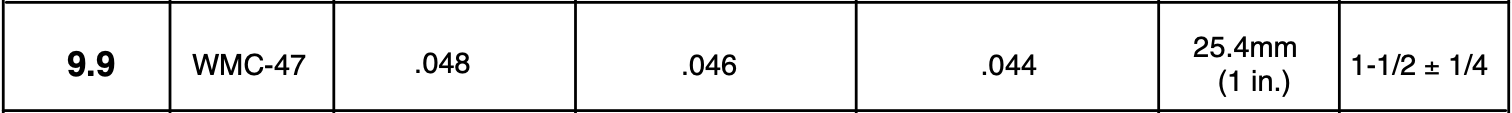

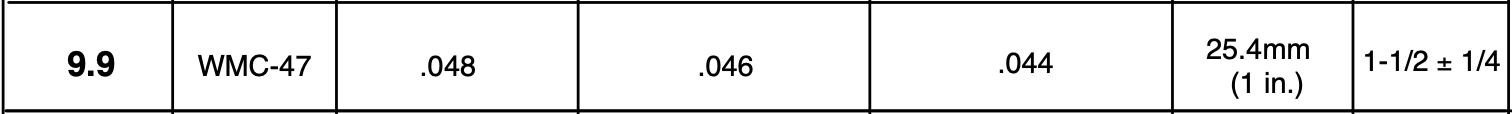

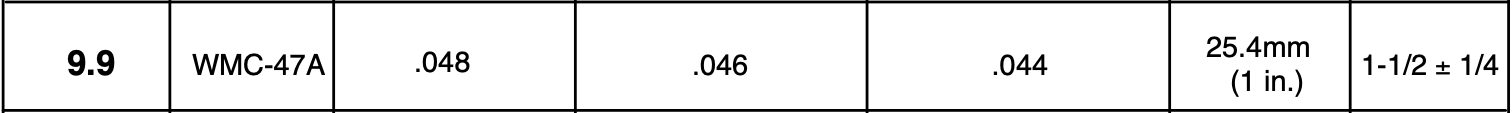

Restricted Fuel Flow and Incorrect High-Speed Jet:

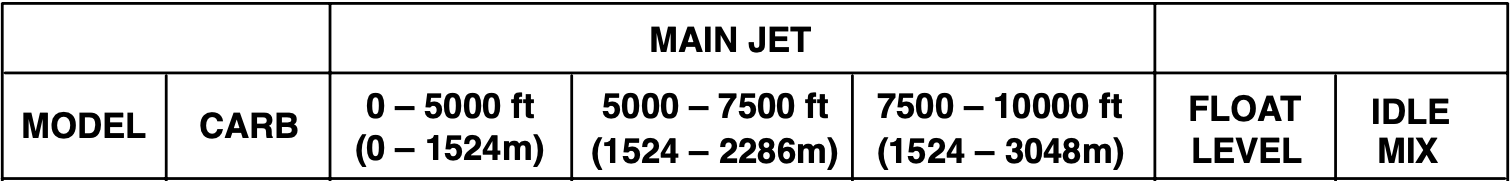

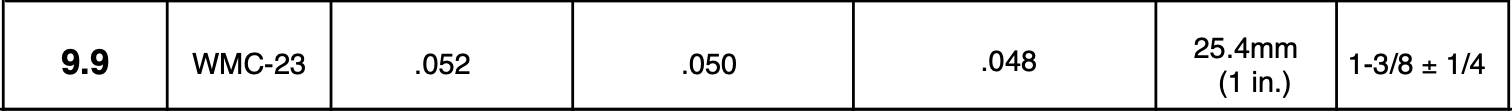

A lean-running engine can also result from restricted fuel flow to the carburetor. Regularly check and clean fuel lines and filters to ensure unobstructed fuel delivery. Moreover, an incorrect high-speed jet can contribute to a lean mixture. Consult the main jet chart provided by the manufacturer and replace the jet with the appropriate size to achieve the correct fuel-to-air ratio.

Idle Mixture Adjustment and Air Leakage:

An excessively lean idle mixture can affect engine performance, particularly during low-speed operation. Adjusting the idle mixture to run richer by turning the idle mix screw counterclockwise can restore proper fuel delivery. Additionally, air leakage into the fuel system, caused by loose fittings in fuel line connections, hose clamps, fuel pump, or the fuel outlet tube in the tank, can lead to a lean-running engine. Careful inspection and tightening of these components can help prevent air leaks.

Anti-Siphon Valve Inspection:

Lastly, a restricting anti-siphon valve in the fuel system can impede fuel flow, leading to a lean mixture. Inspect the valve and consider testing the engine without the valve to determine its impact on fuel flow.

Conclusion:

A lean-running 1994 thru 2001 Mercury 9.9hp outboard engine can hinder its performance and efficiency. By understanding the potential causes and implementing the recommended corrective actions, such as securing the carburetor, adjusting the float level, cleaning components, and ensuring proper fuel flow, boaters can ensure their engine operates optimally, delivering the reliable power needed for an enjoyable and smooth boating experience.